Why Rubber Sleeves are Essential for Chemical Resistance: A Comprehensive Guide

2025-12-17

Why Rubber Sleeves are Essential for Chemical Resistance

In an era where safety and durability are paramount, the use of rubber sleeves has become increasingly vital across various industries. As companies strive to protect both their workers and equipment in chemical handling environments, understanding the significance of rubber sleeves in providing chemical resistance is crucial. This article delves into the properties, applications, and benefits of rubber sleeves, highlighting why they are indispensable in today’s chemical manufacturing landscape.

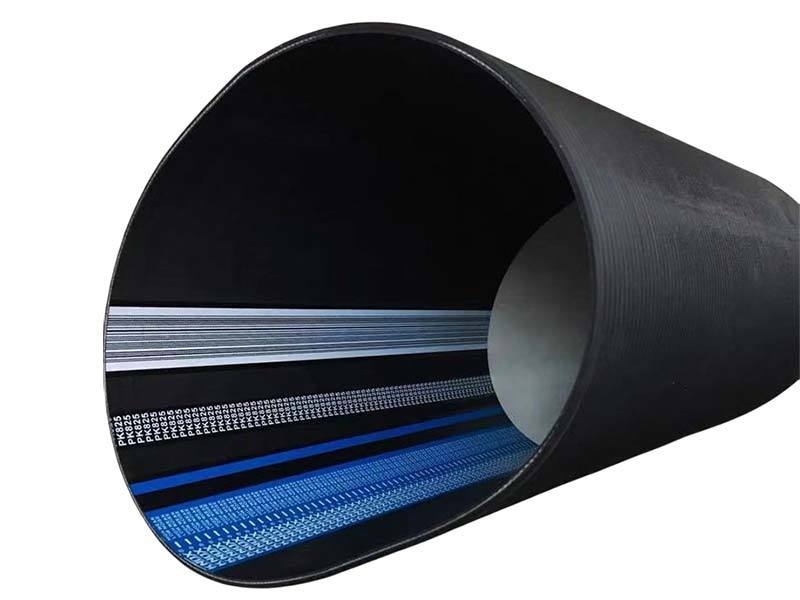

Understanding Rubber Sleeves

Rubber sleeves are protective coverings made from rubber compounds designed to shield against chemical exposure, abrasion, and environmental factors. Their versatility and adaptability make them suitable for a wide range of applications, from industrial settings to medical environments.

The Composition of Rubber Sleeves

Rubber sleeves are composed of various rubber materials, including natural rubber, synthetic rubber (like neoprene, nitrile, and EPDM), and specialized blends. Each type of rubber offers unique properties that cater to specific chemical resistance needs.

- **Natural Rubber**: Known for its excellent elasticity and tensile strength, natural rubber is often used in applications requiring flexibility.

- **Nitrile Rubber**: This synthetic rubber provides superior resistance to petroleum-based oils and chemicals, making it ideal for automotive and industrial applications.

- **EPDM Rubber**: Known for its outstanding weather resistance, EPDM is great for outdoor applications and can withstand harsh environmental conditions.

Key Properties of Rubber Sleeves

Rubber sleeves exhibit several critical properties that enhance their effectiveness in chemical resistance:

- **Chemical Resistance**: Depending on the type of rubber used, these sleeves can withstand exposure to a variety of chemicals, including acids, bases, and solvents.

- **Durability**: Rubber is inherently resistant to wear and tear, making these sleeves suitable for heavy-duty applications.

- **Flexibility**: The elasticity of rubber allows for easy installation and movement, providing a snug fit around equipment or piping.

- **Temperature Resistance**: Certain rubber types can withstand extreme temperatures, ensuring reliability in various operational conditions.

Applications of Rubber Sleeves

Rubber sleeves serve a multitude of purposes across different industries, ensuring safety and efficiency.

Chemical Manufacturing

In chemical manufacturing plants, rubber sleeves are essential for protecting pipes, valves, and other equipment from corrosive substances. They provide a barrier that prevents chemical leaks and protects workers from hazardous exposure.

Automotive Industry

In the automotive sector, rubber sleeves are used on hoses, wires, and connectors to shield them from oil, fuel, and other chemicals. They prevent degradation and enhance the longevity of critical components, ensuring vehicle safety.

Electronics

Rubber sleeves are also utilized in the electronics industry to provide insulation for wires and components. They protect against chemical exposure and environmental factors, helping to maintain the integrity of electronic devices.

Medical Applications

In medical settings, rubber sleeves are crucial for protecting instruments and tubing from contamination. Their chemical resistance properties ensure that they can withstand sterilization processes while maintaining safety standards.

Benefits of Using Rubber Sleeves

The advantages of incorporating rubber sleeves into various applications cannot be overstated. Below are some of the primary benefits:

Enhanced Safety

By providing a protective barrier against hazardous chemicals, rubber sleeves significantly reduce the risk of accidents and injuries in the workplace. This is especially important in industries where exposure to toxic substances is prevalent.

Cost-Effective Solution

Rubber sleeves extend the lifespan of equipment by providing protection against wear and corrosive substances. This longevity translates to cost savings over time, as businesses can avoid frequent replacements.

Improved Performance

With rubber sleeves in place, equipment can perform more efficiently without the risk of damage from chemical exposure. This results in better operational performance and reduced downtime for maintenance.

Customization Options

Rubber sleeves can be customized to fit specific applications, ensuring a perfect fit for any equipment or piping. Various sizes, colors, and thicknesses are available to meet the diverse needs of different industries.

Choosing the Right Rubber Sleeve

Selecting the appropriate rubber sleeve involves several considerations to ensure optimal performance and safety.

Identify the Chemicals Involved

The first step is to understand the specific chemicals that the rubber sleeve will be exposed to. Different rubber materials provide varying levels of resistance to different substances, so it’s crucial to select a type that can withstand the specific chemical environment.

Consider the Environmental Conditions

Think about the operating environment, including temperature extremes, exposure to UV light, and potential physical wear. This will help determine the best rubber material for the application.

Assess the Required Thickness

The thickness of the rubber sleeve can impact its durability and flexibility. Thicker sleeves offer more protection but may reduce flexibility, while thinner sleeves provide ease of installation but less protection.

Installation and Maintenance of Rubber Sleeves

Proper installation and maintenance of rubber sleeves are essential for ensuring their efficacy in protecting against chemical exposure.

Installation Guidelines

1. **Clean the Surface**: Before installing the rubber sleeve, ensure that the surface is clean and free from debris.

2. **Fit Properly**: Slide the sleeve over the area to be protected, making sure it fits snugly without being overly tight.

3. **Secure Edges**: Use adhesive or clamps to secure the edges of the sleeve, preventing it from slipping during operation.

Maintenance Practices

To prolong the lifespan of rubber sleeves, regular inspections should be conducted to check for signs of wear, tear, or chemical degradation. Any damaged sleeves should be replaced immediately to maintain safety standards.

FAQs About Rubber Sleeves and Their Chemical Resistance

1. What types of chemicals can rubber sleeves resist?

Rubber sleeves can resist a variety of chemicals depending on the type of rubber used. For example, nitrile rubber is excellent for oil and fuel resistance, while EPDM is suitable for acids and bases.

2. How do I know if a rubber sleeve is right for my application?

Consider the specific chemicals, environmental conditions, and required thickness for your application. Consulting with a supplier can also provide guidance on the best options available.

3. How long do rubber sleeves typically last?

The lifespan of rubber sleeves depends on several factors, including the type of rubber, exposure to chemicals, and environmental conditions. Regular inspections can help identify when replacement is necessary.

4. Can rubber sleeves be reused after cleaning?

In many cases, rubber sleeves can be cleaned and reused, provided they are not damaged and still offer adequate chemical resistance. It’s essential to inspect the sleeves for wear before reuse.

5. Are there any safety standards for rubber sleeves in industrial applications?

Yes, various safety standards govern the use of rubber products in industrial settings. Always ensure that the rubber sleeves meet relevant safety certifications and regulations for your industry.

Conclusion

Rubber sleeves play a critical role in enhancing chemical resistance across various industries. Their unique properties, coupled with the benefits they offer, make them an essential component in ensuring safety and efficiency. By understanding the significance of rubber sleeves, selecting the right materials, and following proper installation and maintenance practices, businesses can protect their workers, equipment, and bottom line. Investing in high-quality rubber sleeves is not only a smart choice for operational efficiency but also a commitment to safety in the workplace.

TAG:

Contact Us

E-mail:

hy-1@hanyubelt.com

Manager Peng:

+8613758603868

Lina:

+8618989621567

Address:

No.109 -2, Kaiyuan Street, Zhu'ao Town, Sanmen County, Zhejiang Province